I will be using this post to place any information I find about print production methods. A lot of my research will be primary research as I am hoping to visit studios or printers, however this is just to show that I have also done some further research.

Lithographic Printing

The main printing process used throughout the world and encompasses a number of different terms including:

Offset Printing, Litho, Sheet Fed, Web Offset, Continuous.

It is a planographic process where the image and non-image are on the same flat printing plate. The image areas are processed to accept ink and repel water. The non-inage areas are processed to accept water and reject the greasy ink. So by wetting the plate and then inking it, the image area is able to transfer the ink to a blanket cylinder and then from there to the paper (the offset principle). The printing plate never comes into contact with the paper.

Litho plates are made by a variety of methods but most modern print factories use computer-to-plate (CTP) systems which are created direct from the computer files rather than having to output film first.

Digital Printing

Is primarily used for short runs of less than 1000 or for items that need to be individually personalised with text and/or images. Digital printing requires less set-up than other methods but does not gain from economies of scale.

Digital printing uses a dry ink process where the ink does not permeate the paper unlike wet ink. The dry ink is held in place by applying a layer of fuser oil and a heat process.

Large Format Printing

This process uses inkjet printing machines that can print widths up to 3.5m and virtually any length. Large format printing is usually used to produce short run posters, banners and point of sale material and the end results can be lightfast and permanent.

Silk Screen Printing

This process uses a stencil which is mounted on to a fine screen material. The ink is passed through the stencil and screen onto the substrate.

Screen printing can be used on virtually any substrate and any shape using any kind of ink.

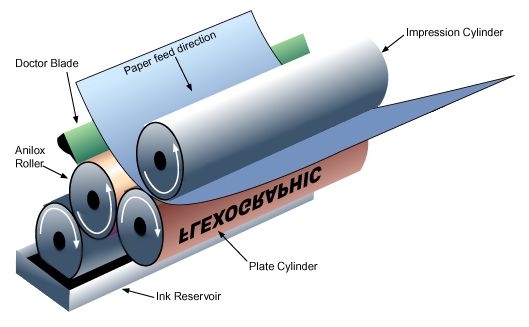

Flexography

This process uses a rubber plate and very thin inks and is similar to the original letterpress printing techniques. This is a specialist process and is used most commonly on plastic carrier bags.

Gravure Printing

This process uses an engraved image which is flooded with ink and the surplus is scraped off with a blade, the plate is then pressed onto the paper. This process can produce very intense colour on very low grade paper and so is a popular process for long runs like Sunday newspaper supplements.

Printing “finishes” such as lamination and Spot UV varnishes are used to increase both the perceived value and quality of a printed item (such as a brochure, folder or data sheet) and also provide ink-protection.

Depending on the desired result and project budget, each of the print finishes has it’s own pros and cons and in any print situation the suitability of a laminate or varnish needs to be considered carefully.

Lamination is the process of using an ultra thin plastic film which can be applied to almost any paper or board and is more commonly used in gloss, silk and matt finishes. A lamination will cover the whole side or sides of a document and cannot be used to cover a specific area alone.

Lamination Pros:

- can be used to enhance the appearance of standard paper boards at relatively low cost and is generally cheaper than a spot uv varnish in most cases

- will make a paper more durable and long lasting and can actually offer some water/grease resistance

- eliminates cracking of ink on creases

- no set up costs

Lamination Cons:

- can only be used to cover a whole side of a document

- matt lamination over a dark colour will show scratches and finger prints, more so than gloss

UV (ultra violet) Varnish is a liquid coating used to ‘mask off’ any area of a design and enhance it (ie. varnishing text, logos or images whilst leaving the remainder of the page unaffected). Unlike a lamination, UV varnishes come in an array of finishes and not only include gloss and matt but also glitter and colour-flip versions as well as many others.

UV Varnish Pros:

- can be used to enhance specific areas such as text, logos or images rather than cover a whole page

- additional substances can be added to varnish to increases its versatility such as glitter

- can be used in conjunction with a laminate and printed over the top to create a more creative and diverse result

UV Varnish Cons:

- if printed over a crease in a document it will crack in the same way ink does

- if printed over text or images will be subject to ‘make ready’ die charges which increases its cost

- due to additional set up required uv varnishing is a longer process than lamination

A neutral Varnish (which is invisible to the eye) may also be used to ‘coat’ or ‘seal’ the ink and can be applied ‘online’ (the varnish is applied directly to the product on the press after the ink has been printed) or ‘offline’ which means it is applied some time after the print process. This is not the same as a Spot UV Varnish will generally cover the whole of a document to prevent ink offset.

Many factors will determine whether a lamination or varnish is used such as budget, usage, and the creative brief and we at Design Inc. are happy to offer advice and expertise for any requirement you might have.

Embossing refers to the creation of an impression of some kind of design, decoration, lettering or pattern on another surface like paper, cloth, metal and even leather, to make a relief. In regular printing or an engraving, plates are pressed against the surface to leave an imprint. In embossing however, the pressing raises the surfaces adding a new dimension to the object.

Embossing is an elegant process that changes the nature of the material that has been embossed. More often than not it elevates the standard and quality of the product. A notary’s embossed seal can give much weight to a regular piece of paper. Similarly, an embossed wedding card immediately changes the entire meaning conveyed by the invitation. The recipient is informed not only about the wedding but also that it is going to be a high profile wedding and an elegant ceremony.

Embossing thus makes things more beautiful than they originally are. The simplest of object can become pieces of art worthy of the highest praise by using a technique as easy as embossing. Of course, how good an embossed object looks depends entirely on the quality of embossing. Poor quality embossing can completely kill the appeal of an object. However, good quality embossing can make an object positively breathtaking.

Embossing involves the creation of an impression by placing the dies in contact with the stock under high pressure. Different kinds of paper show different kinds of embossed effects. There are also many different kinds of embossing that can be done like blind embossing, tint embossing and glazing to achieve different results. The process of embossing is relatively inexpensive and has many uses.

Embossing is used for aesthetic purposes as well as functional uses in industries. From embossing names on credit cards to embossed Braille books for the blind, embossing has a wide range of applications and uses.

Thus, embossing is a technique that adds elegance and sensuality to any paper or surface.

No comments:

Post a Comment